Plastic Insert Composite Decking Waterproofing

Introduction

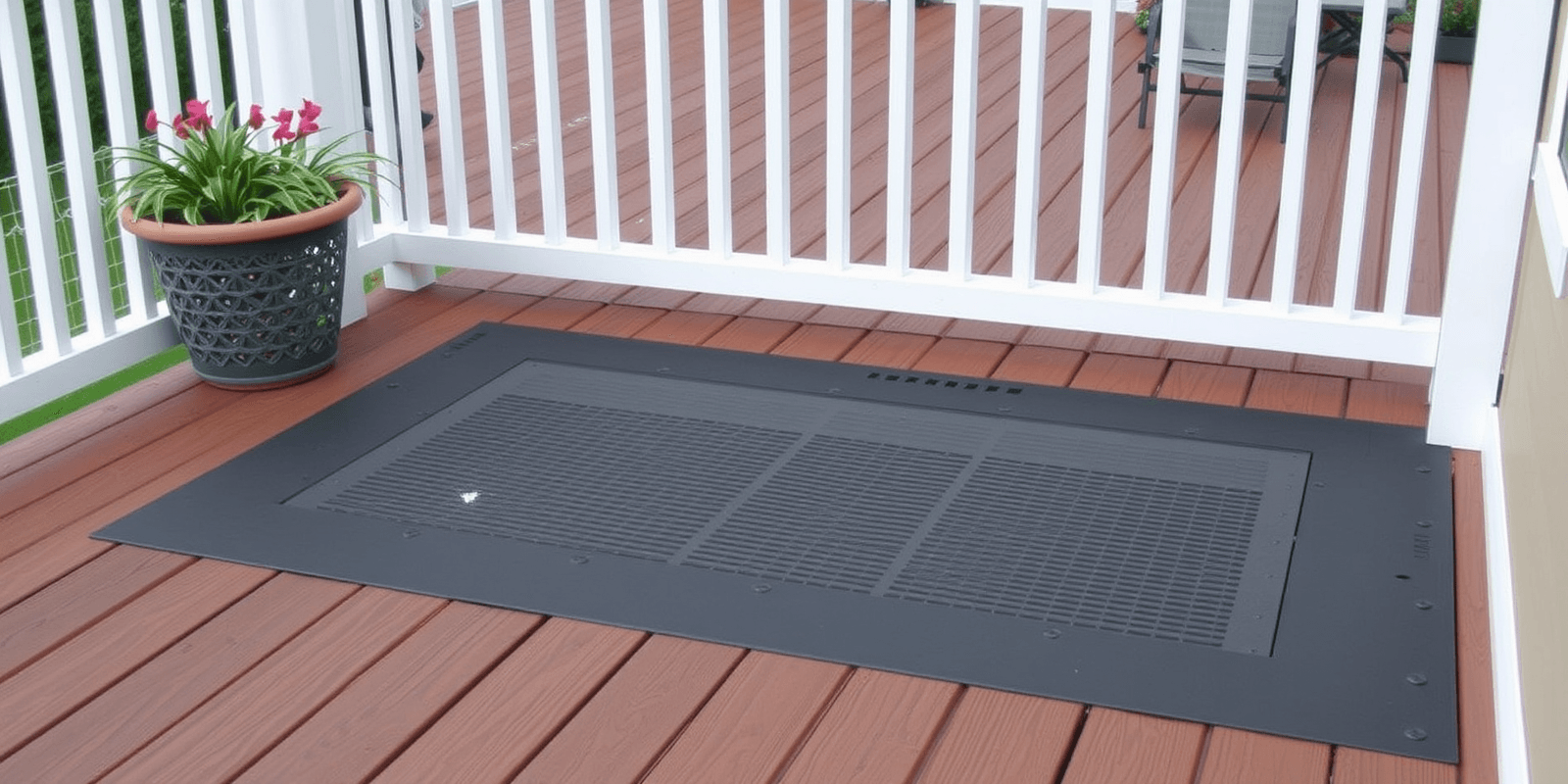

In recent years, the construction industry has seen a significant shift towards sustainable building materials. Among these innovations, plastic insert composite decking has emerged as a popular choice for outdoor living spaces due to its durability, low maintenance, and aesthetic appeal. However, one of the key challenges in using composite decking is ensuring it remains waterproof. This article delves into the materials and techniques used in plastic insert composite decking to enhance its waterproofing capabilities. We will also explore case studies and examples of successful applications.

Materials and Techniques Used

The waterproofing of plastic insert composite decking primarily relies on a combination of advanced materials and innovative manufacturing techniques. These include the use of water-resistant resins, specialized coatings, and unique composite blends that are designed to repel moisture effectively.

One of the primary materials used in enhancing the waterproofing properties of composite decking is polyethylene (PE) or polypropylene (PP). These thermoplastics are known for their excellent water resistance and are often blended with wood fibers to create a strong, durable composite material. Additionally, manufacturers may incorporate UV stabilizers and fire retardants to further enhance the longevity and safety of the decking.

Specialized coatings are another critical component in improving the waterproofing of plastic insert composite decking. These coatings are typically applied during the manufacturing process and serve as a barrier against water penetration. For example, a silicone-based coating can provide an additional layer of protection against moisture, while also enhancing the overall aesthetics of the deck.

Case Studies and Examples

Several successful applications of plastic insert composite decking have demonstrated the effectiveness of these waterproofing techniques. One notable example is the installation of composite decking at the National Building Museum in Washington D.C. The project utilized a blend of recycled plastic and wood fibers, along with a special UV-resistant coating, to create a long-lasting, weather-resistant surface that could withstand heavy foot traffic and extreme weather conditions.

Another example is the use of composite decking in coastal areas where high humidity and saltwater exposure pose significant challenges. A case study from a coastal community in Florida showcased how the integration of water-resistant resins and specialized coatings helped protect the decking from corrosion and degradation, thereby extending its lifespan significantly.

Conclusion

Plastic insert composite decking offers numerous advantages, particularly in terms of sustainability and ease of maintenance. By leveraging advanced materials and manufacturing techniques, manufacturers can significantly enhance the waterproofing capabilities of composite decking. As demonstrated by various case studies, these innovations not only improve the performance of the decking but also contribute to its overall longevity and aesthetic appeal. As the demand for sustainable building solutions continues to grow, plastic insert composite decking is likely to play an increasingly important role in modern construction projects.

Reviews

There are no reviews yet.