“`html

The Manufacturing Process Behind WPC Capped Decking Factories

Introduction

WPC (Wood Plastic Composite) capped decking has gained significant popularity in recent years due to its durability, low maintenance, and eco-friendly nature. This blog post aims to provide an in-depth look at the manufacturing process behind WPC capped decking, including the raw materials, machinery used, quality control measures, and final product testing procedures. By understanding these processes, you can better appreciate the craftsmanship and innovation that goes into creating this high-quality decking material.

Raw Materials Used in WPC Capped Decking Production

The production of WPC capped decking begins with the selection of high-quality raw materials. These include:

- Wood Flour: Derived from recycled wood waste, this serves as the primary filler material for the composite.

- Polymer Resin: Typically made from recycled plastic, this resin acts as the binding agent for the composite material.

- Additives: Various additives such as UV stabilizers, colorants, and lubricants are added to enhance the properties of the final product.

These raw materials are carefully mixed in precise proportions to ensure the desired characteristics of the WPC capped decking.

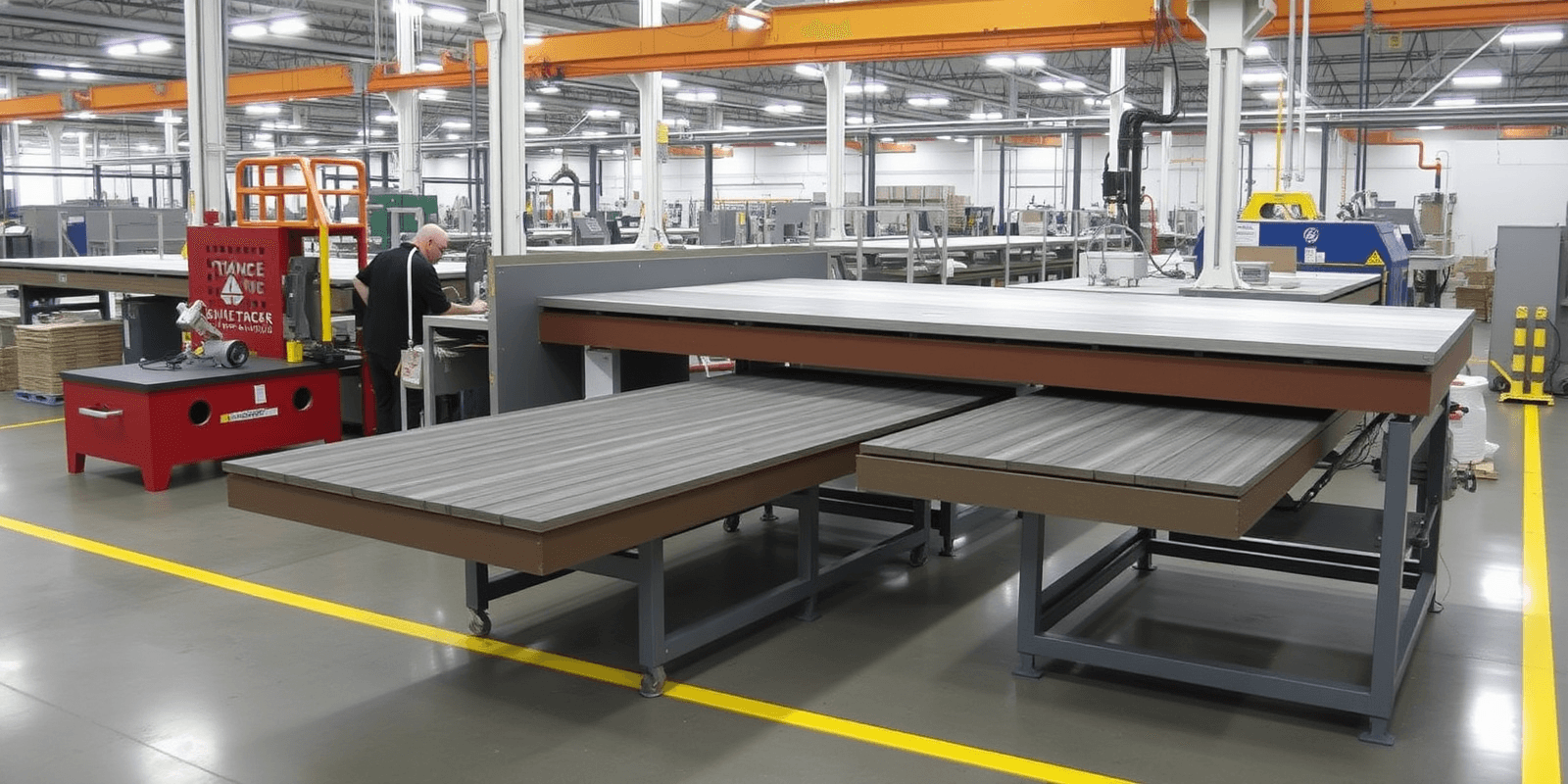

Machinery Used in WPC Capped Decking Production

The manufacturing process of WPC capped decking involves several stages, each utilizing specialized machinery:

- Mixing and Extrusion: The raw materials are first mixed in a large blender and then fed into an extruder. The extruder heats and mixes the materials until they form a homogeneous blend. This blend is then forced through a die to create the desired shape of the decking board.

- Cooling and Sizing: As the extruded material exits the die, it is rapidly cooled using water baths or air cooling systems to set the shape. It then passes through sizing equipment to ensure uniform dimensions.

- Capping: The final step involves applying a protective cap layer to the surface of the decking board. This cap layer is typically made from a different type of polymer that offers enhanced resistance to weathering, stains, and scratches. The capping process is crucial in extending the lifespan of the decking material.

Quality Control Measures in WPC Capped Decking Production

To ensure the highest standards of quality, WPC capped decking factories implement rigorous quality control measures throughout the manufacturing process:

- In-Process Inspections: Regular inspections are conducted during each stage of production to identify any defects or inconsistencies in the raw materials, mix ratios, or machine settings.

- Final Product Testing: Once the decking boards are fully manufactured, they undergo a series of tests to evaluate their physical properties, such as tensile strength, impact resistance, and moisture absorption. These tests help verify that the products meet industry standards and customer expectations.

- Environmental Compliance: Manufacturers also adhere to strict environmental regulations regarding the disposal of waste materials and the use of non-toxic additives, ensuring that their operations have minimal ecological impact.

Final Product Testing Procedures

The final product testing procedures for WPC capped decking are designed to assess the durability and performance of the decking boards under various conditions. Common tests include:

- Weathering Tests: Samples are exposed to accelerated weathering conditions, simulating years of exposure to sunlight, rain, and temperature fluctuations. This helps determine the long-term color retention and structural integrity of the decking.

- Stain Resistance Tests: The ability of the decking to resist staining from common household substances is evaluated by applying known stains and measuring their penetration depth.

- Scratch Resistance Tests: The surface hardness and scratch resistance of the decking are tested using standardized methods, ensuring that the capping layer provides adequate protection against everyday wear and tear.

Conclusion

The manufacturing process behind WPC capped decking involves a combination of advanced technology, precise raw materials, and stringent quality control measures. From the initial mixing of wood flour and polymer resins to the application of the protective cap layer, each step is meticulously executed to produce a durable, low-maintenance, and environmentally friendly decking solution. Understanding these processes not only highlights the craftsmanship involved but also underscores the importance of selecting high-quality WPC capped decking for your outdoor projects.

“`

Reviews

There are no reviews yet.