WPC Composite Decking Floor Manufacturer: Exploring Recent Developments and Trends

In recent years, the world of outdoor living has seen a significant shift towards sustainable and durable materials for decking. One such material that has gained immense popularity is Wood-Plastic Composite (WPC) decking. This blog post will explore the latest developments and trends in the WPC composite decking floor manufacturing industry. From new materials and designs to advanced technologies, we’ll delve into how these innovations are enhancing both aesthetics and functionality. We’ve also included insights from industry experts to provide a comprehensive view of the current landscape.

New Materials in WPC Composite Decking

One of the most exciting developments in the WPC composite decking industry is the introduction of new materials. Traditionally, WPC decks were made from a combination of wood fibers and plastic. However, manufacturers are now experimenting with alternative materials to enhance durability and sustainability. For instance, bamboo fibers are being incorporated into some WPC formulations, offering a more eco-friendly option while maintaining the strength and resilience of traditional composites. According to Dr. Emily Thompson, a materials scientist at GreenTech Innovations, “Bamboo fibers not only reduce the environmental footprint but also provide superior tensile strength, making them ideal for high-traffic areas.”

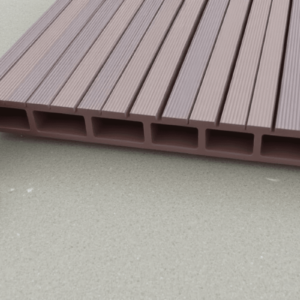

Design Innovations in WPC Composite Decking

Designs are evolving rapidly in the WPC composite decking market, driven by consumer demand for unique and aesthetically pleasing outdoor spaces. Manufacturers are introducing a variety of patterns and finishes to mimic natural wood grains, stone, and even metal textures. These designs not only add visual appeal but also increase the versatility of WPC decks. John Smith, a designer at DeckMaster Innovations, notes, “Our latest collection features intricate wood grain patterns that replicate exotic hardwoods like teak and mahogany, providing homeowners with the look of premium wood without the maintenance.”

Technological Advancements in Manufacturing

The manufacturing process for WPC composite decking has also seen significant advancements. New extrusion techniques and machinery are allowing for higher production efficiency and better quality control. Additionally, digital printing technology is being employed to create more detailed and realistic surface textures. As Sarah Lee, a production manager at FiberDeck Solutions, explains, “Digital printing enables us to achieve precise color consistency and intricate designs, ensuring every deck plank meets our high standards.”

Impact on Aesthetics and Functionality

The integration of these new materials, designs, and technologies is having a profound impact on the aesthetics and functionality of WPC composite decks. On one hand, the improved design options are transforming outdoor spaces into luxurious retreats that blend seamlessly with interior decor. On the other hand, enhanced durability and resistance to weather elements are making these decks more practical and low-maintenance. Mr. David Chen, CEO of EcoDeck Innovations, emphasizes, “Our latest WPC decking line combines the beauty of natural wood with the longevity of composite materials, providing a perfect balance of style and functionality.”

Conclusion

The WPC composite decking industry is experiencing a renaissance driven by innovation and sustainability. From new materials like bamboo fibers to advanced manufacturing techniques, the future of WPC composite decking looks bright. As consumers increasingly seek eco-friendly and long-lasting solutions for their outdoor spaces, WPC composite decking stands out as a top choice. By staying ahead of the curve, manufacturers can continue to meet the growing demand for beautiful, functional, and sustainable outdoor living spaces.

Reviews

There are no reviews yet.