WPC Floor Installation Guide: Tips for Wholesale Buyers

Introduction

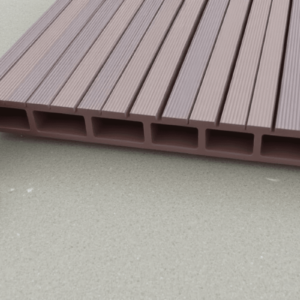

Welcome to our comprehensive guide on installing WPC (Wood Plastic Composite) flooring, designed especially for wholesale buyers. This guide aims to provide you with detailed insights into the preparation, tools required, step-by-step instructions, and cost-saving tips for bulk purchases. Whether you’re renovating your home or commercial space, understanding these aspects can significantly enhance your project’s outcome.

Preparation for WPC Flooring Installation

Before diving into the installation process, it is crucial to prepare the subfloor properly. Ensure that the surface is clean, dry, and level. Any unevenness should be corrected using self-leveling compound or similar materials. Additionally, inspect the area for any potential moisture issues, which could compromise the longevity of your WPC flooring. Proper preparation not only ensures a smooth installation but also prevents future problems like warping or buckling.

Tools Required for WPC Flooring Installation

To install WPC flooring effectively, you’ll need a variety of tools. These include a measuring tape, circular saw, jigsaw, utility knife, tapping block, pull bar, drill, screws, and adhesive. Having these tools at hand will streamline the installation process and ensure precision. For wholesale buyers, consider purchasing in bulk to save costs. Many suppliers offer discounts for larger orders, making this an excellent opportunity to stock up on essential tools.

Step-by-Step Instructions for Installing WPC Flooring

- Measure and Plan: Accurately measure the room dimensions and plan the layout. Start from the center of the room and work your way outwards to minimize cuts and waste.

- Cut the First Row: Use a circular saw or jigsaw to cut the first row of planks to fit the room dimensions. Ensure the first plank is aligned with the wall.

- Lay the First Row: Install the first row of planks by clicking them together. Use a tapping block and mallet to secure the joints.

- Install Subsequent Rows: Continue laying rows, staggering the joints between each row for added stability. Use a pull bar to keep the planks tight against the walls.

- Cut Around Obstacles: For areas around obstacles like cabinets or doorways, use a jigsaw or coping saw to make precise cuts.

- Final Touches: Once all planks are installed, add transition strips or moldings to cover gaps and edges. Trim any excess material with a utility knife.

Cost-Saving Tips for Bulk Purchases

Buying WPC flooring in bulk offers significant cost savings. Here are some tips to maximize your savings:

- Negotiate Discounts: When ordering large quantities, negotiate for better prices. Many wholesalers offer volume discounts that can reduce the overall cost per unit.

- Choose Quality Over Quantity: While it might be tempting to opt for cheaper options, investing in high-quality WPC flooring ensures durability and longevity, ultimately saving money in the long run.

- Plan Ahead: Anticipate your needs and order well in advance to take advantage of seasonal sales and promotions.

- Consider Second-Hand Options: If budget constraints are a concern, explore second-hand or refurbished WPC flooring options. These can often be found at a fraction of the cost of new products.

Conclusion

Installing WPC flooring can be a rewarding DIY project, especially when done correctly. By following the steps outlined in this guide and taking advantage of cost-saving measures, you can achieve a beautiful, durable floor that enhances your space. Remember, proper preparation and the right tools are key to a successful installation. Happy building!

Reviews

There are no reviews yet.